Solving complex systems is difficult, but sometimes one gets lucky and finds the solution through throwing a dart at a problem and finding that it stuck to the target. This is how I felt when I finally found the right combination to solve my problem with gold loss in my Sluice System.

“There must be an answer”…that’s what I was thinking looking at the results of my experiments to find the perfect combination to solve my gold loss situation with my Sluice. (See Part 5.) Though I was getting good results simply using Raised Rubber Ribbing with my Cleangold Sluice, it still wasn’t up to the goal I was seeking. What was that goal? To keep most, if not all of the heavy material passing through my Sluice from 1/4” on down into the invisible range. What I thought was needed is some type of material or perhaps device to cause a change to the angle of attack for flat and barrel shapes running down a sluice.

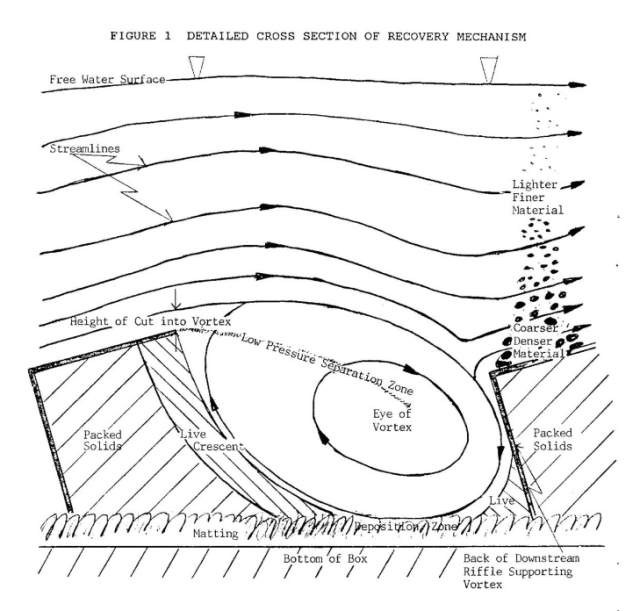

Explanation: Water pressure pressing upon an object causes that object to react to that pressure depending on the weight and shape it has. An example of this effect is when a light particle, particularly, let us say, a flat thin round object confronts a pressure such as from water, it has a tendency to act like let’s say, a surf board, and ride the current at the level conducive to its weight and shape. Fundamentally, this is one of the reasons why a Riffle or like objects don’t have much success with capturing various weights and shapes.

Sometime later while doing a gold show, I was approached by someone with a sample of gold and black sand mix. He told me that the sample was ran through a new device that used only Matting, and was wondering if Cleangold could get better results. Not being able to check out any difference at a gold show, I decided to take a quick look at the Matting being used in this new device. Fortunately the inventor of this new device was present, so I had a talk with him and obtained a piece of the Matting being used. After the show was over, I found time to trace where to obtain a piece big enough to check out its performance in real conditions.

About a month later, the spring weather was just right to take my experimental, Cleangold Highbanker down to a river for a workout. Everything was the same set up I usually use except I added a full plate of the new Matting I obtained for experimental purposes. Putting a large tub in front of the mouth of my Highbanker to catch the tailing for further inspection of gold loss, I turned on my motor and pump, adjusted the pitch, roll and flow on the Sluice, then started shoveling bank gravel into the Hopper. After several hours of shoveling gravel, it was time to check the results of my experiment.

As the water flow stopped running down my sluice, I could see a fair amount of gold on the first plate which consisted mostly of a Slick Plate with Raised Rubber Ribbing. The next plate was Cleangold which needs to be processed to see the gold, and the last plate was the new Matting which also needs to be processed to see the results. Before checking the last 2 plates of the sluice materials, I decided to see what was the gold loss from the sluice that would be sitting in the tailing tub. It took us some time to break down the tailing, (yes I do have “sidekicks” on hand), but to our surprise, we couldn’t find any loss. What!? How can that be? Finally I broke down the remaining 2 plates of material on the sluice and examined the results hoping to find why I didn’t lose any of the gold. The only knowledge that came from the experiment was that the lead plate material caught most of the gold and the second caught somewhat less and the third plate caught what was left.

Hint: When checking your Sluice for efficiency, examine for gold along the edge of the sluice mouth. If gold is present, chances are that you are losing gold. One solution that some Sluice/Highbanker manufactures do to solve this problem is to sell you an extension piece called a “Long Tom.” In the old days Sluice/Long Tom combinations could run from 250’ to 2000’ long! One reason for this was that they were using their Sluices not only for capturing gold, but to also for classifying the cobble/gravel mix as well as an attempt to handle the water pressure problem.

There was much to think about. If I’m not losing gold, is it the sequence of the material on the sluice or is it the materials itself or what?

Another week went by and with much thinking, it was decided to switch the sequence of the plates with their different materials and try it again. Once again at the same spot on the river the Highbanker was set up just like before except that the material plates were arranged in a different sequence. After another run of the same gravels, the tailing was panned for gold loss. To everyone’s surprise the results were the same as last week including the lead plate collecting most of the gold! It appeared that the sequence of the different matting’s wasn’t the reason for its superior performance. Perhaps it is Synergistic compatibility that is one of the keys to its success. What am I talking about?

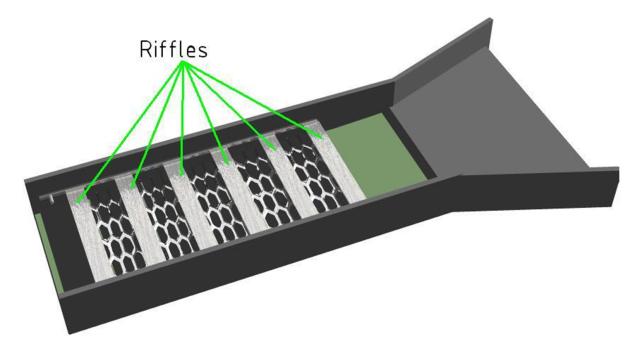

Explanation: Explanation: When designing a working system like let’s say, a racing car, and other systems are involved to complete it, these systems must compliment the actions of each other in order to work in a proper way. These systems working together in a complimentary way would be called Synergistic. The reverse of this, for instance in the mining world, we can find situations that reflect just the opposite of synergistic systems as let’s say, putting Riffles on top of Expanded Metal. These 2 systems work well onto themselves, but combining them into one unit by stacking one on top of the other defeats the outcome of their purpose. Why? Because each system works at different water pressures, which makes them un-synergistic so they work against each other. Is there a solution to this particular problem? Yes…run them together, but separately by proper design parameters.

With the success of the initial experiments, it was now time to find out just how little of the different materials was needed to do the magic before they failed and what sequence of the materials was needed if any. Without going through all of the experiments that were done, what has been settled upon is my Cleangold Products which I offer on the market to you. With the new revolutionary Cleangold Sluices and Highbankers, you can take on mining recovery situations from beach to the river with amazing results from total black sand to regular gravels in the 1/4”to the deep invisible range such as many Hard Rock Mines are processing, and can process from 10 to 20 pounds a minute clean up system to 10 tons an hour production use. In conclusion: if you have any questions about our system, or if you think that you have a better system in recovery as well as the economical cost, please bring it on head to head with us. Any takers?

Cheers.

The Fossicker,

Dennis Katz

Where can I see your clean gold sluices with their prices?? I would like to purchase one.

LikeLike

I have your pyramid pro pan and have used it in Lynx Creek in Prescott Oregon..

It’s an answer to prayer. Performs outstandingly and I don’t have to clean it out very

often.. The gold is always in the trap!!!!

LikeLike

Correction;;; Prescott Arizona. I was thinking of the beach gold in Oregon…

LikeLike